Plastic Yarn/ Tape Extruder/ Extrusion Machine Manufacturer

Peformance And Characteristics:

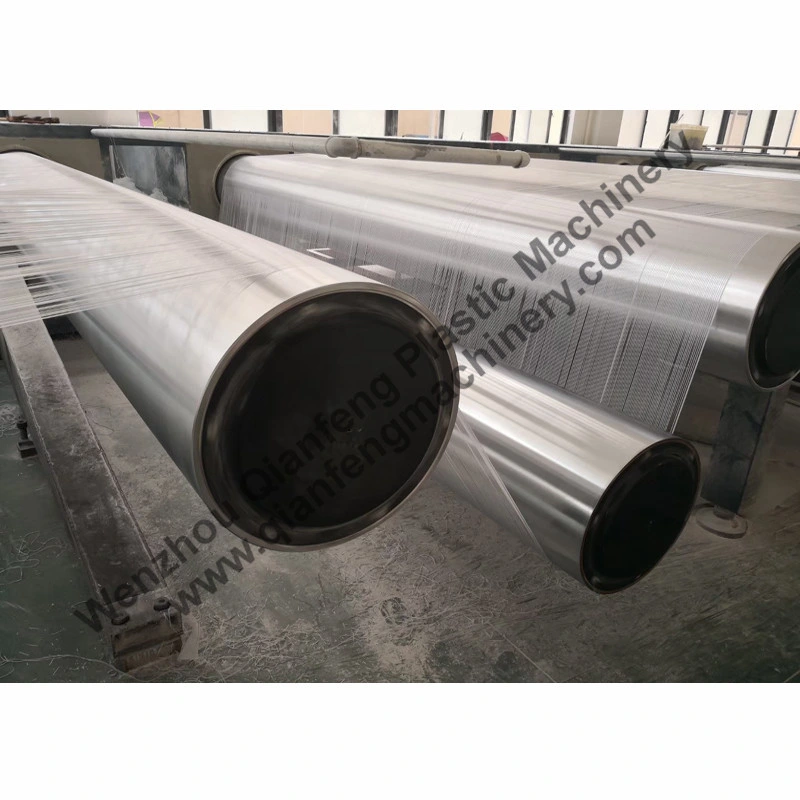

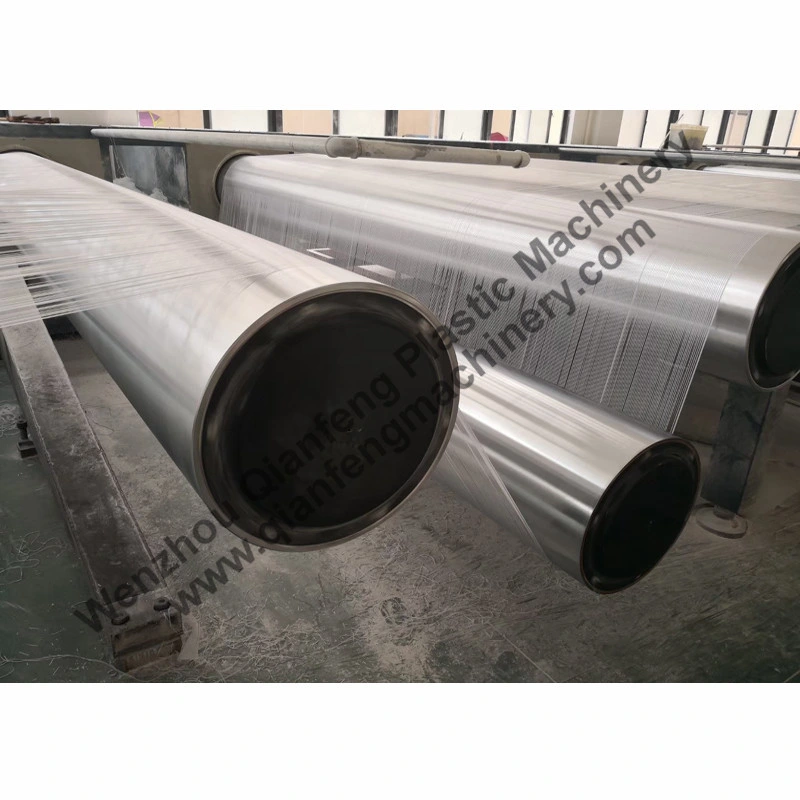

*The machine using materials of Polypropylene(PP) or high density Polyethylene(HDPE), through heating, extruding, splitting the film into tapes, stretching and forming flat tapes. Then winding on the bobbins by winder, finally put the bobbins with tapes on circular loom for weaving.

*After improving many times, the machine can use 100%recycling material, powder and granule material to produce tapes. The screw and cylinder of extruder are made of 38CrMoA1A alloy steel, the hardness is over HV950 after nitriding treatment. Helical gear reducer made of 20CrMnTi alloy steel is applied to the gear reducer of extruder. The traction devices adopts touch screen to change speed which enable stable drawing.

Main Technical Parameters:

Machine photos and patents:

Old factory

New factory:

Contact Information

Peformance And Characteristics:

*The machine using materials of Polypropylene(PP) or high density Polyethylene(HDPE), through heating, extruding, splitting the film into tapes, stretching and forming flat tapes. Then winding on the bobbins by winder, finally put the bobbins with tapes on circular loom for weaving.

*After improving many times, the machine can use 100%recycling material, powder and granule material to produce tapes. The screw and cylinder of extruder are made of 38CrMoA1A alloy steel, the hardness is over HV950 after nitriding treatment. Helical gear reducer made of 20CrMnTi alloy steel is applied to the gear reducer of extruder. The traction devices adopts touch screen to change speed which enable stable drawing.

Main Technical Parameters:

| Model | Diameter of screw(mm) | Rotational speed of screw (r/min) | Width of Die(mm) | Model of reducer | Motor power of extruder (kw) | Heating power of extruder (kw) | Power of driving motor (kw) | Heating power of the oven (kw) | Drawing rate | Production capacity (kg/h) | Drawing speed(m/min) | Installation dimension (L×W×H)mm | Weight (kg) |

| SJ-FS115/B800 | 115 | 25-75 | 800 | 250 | 30 | 36 | 7.5 | 15 | 4-12 | 50-100 | 50-150 | 11300×1500×1300 | 6500 |

| SJ-FS120/B1000 | 120 | 23-70 | 1000 | 250 | 30 | 43 | 7.5 | 20 | 4-12 | 60-120 | 50-150 | 14700×1750×1300 | 8000 |

| SJ-FS120/B1200 | 120 | 23-70 | 1200 | 250 | 30 | 47 | 7.5 | 24 | 4-12 | 70-140 | 50-150 | 16500×2050×1300 | 10000 |

| SJ-FS135/B1600 | 135 | 22-65 | 1600 | 280 | 37 | 77 | 7.5 | 30 | 4-12 | 90-180 | 50-150 | 20000×2600×2200 | 16000 |

| SJ-FS140/B1800 | 140 | 22-65 | 1800 | 280 | 37 | 80 | 11 | 30 | 4-12 | 100-200 | 50-150 | 20000×2950×2200 | 17000 |

| SJ-FS145/B2000 | 145 | 20-60 | 2000 | 300 | 45 | 86 | 11 | 30 | 4-12 | 110-240 | 50-150 | 21000×3400×2200 | 20000 |

| SJ-FS150/B2200 | 150 | 20-60 | 2200 | 300 | 55 | 86 | 11 | 30 | 4-12 | 120-260 | 50-150 | 22000×3700×2200 | 21500 |

| SJ-FS150/B2400 | 150 | 20-60 | 2400 | 300 | 55 | 92 | 15 | 32 | 4-12 | 140-280 | 50-150 | 22000×4000×2200 | 23000 |

| SJ-FS160/B2600 | 160 | 20-60 | 2600 | 315 | 75 | 96 | 15 | 32 | 4-12 | 140-300 | 50-150 | 23000×4400×2500 | 24500 |

| SJ-FS160/B2800 | 160 | 20-60 | 2800 | 315 | 75 | 106 | 15 | 34 | 4-12 | 160-320 | 50-150 | 23000×4600×2500 | 25000 |

| SJ-FS160/B3000 | 160 | 20-60 | 3000 | 315 | 90 | 106 | 15 | 34 | 4-12 | 160-340 | 50-150 | 24000×4800×2500 | 26500 |

| SJ-FS170/B3200 | 170 | 20-60 | 3200 | 375 | 90 | 112 | 18 | 36 | 4-12 | 180-350 | 50-150 | 25000×5000×2500 | 27500 |

| SJ-FS170/B3500 | 170 | 20-60 | 3500 | 375 | 110 | 118 | 18 | 36 | 4-12 | 200-360 | 50-150 | 25000×5200×2500 | 29000 |

| SJ-FS180/B3800 | 180 | 20-60 | 3800 | 420 | 110 | 118 | 18 | 45 | 4-12 | 200-380 | 50-150 | 25000×5500×2500 | 32000 |

| SJ-FS180/B4000 | 180 | 20-60 | 4000 | 420 | 132 | 145 | 22 | 50 | 4-12 | 350-450 | 50-150 | 25000×6000×2500 | 35000 |

| SJ-FS200/B5000 | 200 | 20-60 | 5000 | 450 | 160 | 155 | 30 | 60 | 4-12 | 500-600 | 50-150 | 26000×6200×2500 | 40000 |

| SJ-FS210/B5800 | 210 | 20-60 | 5800 | 450 | 185 | 165 | 30 | 70 | 4-12 | 500-700 | 50-150 | 26000×6200×2500 | 45000 |

Machine photos and patents:

Old factory

New factory:

Advantage&Service

1. several senior engineers service in our factory, all the year round, with our best after-sales.

2.Machines with quality guarantee for one year, life-long maintenance.

3.A lot of machines can be monitored via Internet, solve customer requirements immediately

4.Several senior engineers innovate and reform the technology continuous, in order to ensure the quality of mechanical stability.

5.Undertake various non-standard machinery, solve the customers' special requirements.

Contact Information

Sales Manager: Rukiya Lam

Tel: 86-018968759159 Fax: 86-577-63682893 Cell: 86-(0)-15158760199

Address: Economic Development Zone, Aojiang, Pingyang, Wenzhou, Zhejiang, ChinaWebsite and Showroom:

wzqianfeng.en.made-in-china.com

http://wzqianfeng.en.made-in-china.com/

wzqianfeng.en.made-in-china.com

http://wzqianfeng.en.made-in-china.com/

Contact us now, expect the cooperation with you!!!!